The common quality problems in the production of greaseproof paper bags mainly come from two aspects. One is the product quality problem caused by the problem of the greaseproof paper material itself; the other is the quality problem of the production process of the greaseproof paper bag and the environmental impact. Explained separately as follows:

1. The problem of the oil-proof paper bag material itself

Grease-proof paper bags are used as printed matter. The nature of the coated paper, the performance of the ink, and the density of printed graphics and texts, etc., all affect the quality of the printing of the grease-proof paper bags. If you use poorly formed coated paper to print, due to the inconsistency in the size of the ink absorption and the absorption speed in the format, it will cause paper tightness, evenness, smoothness, and quantitative changes in moisture. If the ink printing layer is too thick or thick, the wetting, spreading, and penetrating ability of the binder molecules will be poor, the movement of the molecules between each other will be relatively less active, and the mechanical bonding force will be small.

2. The influence of process operation and printing environment on the quality of greaseproof paper bags

When coating the greaseproof paper, first coat a layer of adhesive on the surface of the plastic film. After drying, it still fails to meet the requirements of the coating. In this case, increase the concentration of the solvent to dilute the adhesive for quick-drying, but if the moisture content is too high, air bubbles will easily appear when the film is pressurized, which will then peel and fall off. At the same time, the film is easy to absorb grease, moisture, dust, and other substances in the air, thereby reducing its surface function. Excessive humidity will also affect the volatilization of the solvent in the adhesive. Too much residual solvent will cause air isolation in the film and make the film not stick up. At the same time, uneven roller pressure, uneven rubber roller, and dirt on the rubber roller will cause wrinkles during the film coating.

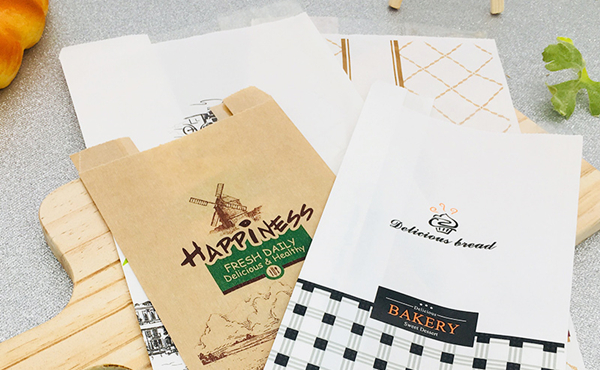

Xiamen Kolysen Packaging Co., Ltd.

The products produced and processed independently by kolysen packaging are mainly greaseproof paper and extended products, greaseproof paper bags, baking cake trays, candy paper, hamburger paper, etc. The products have been supplied to foreign customers for a long time, and the foreign markets spread across Asia, Europe, America, Oceania, and the Middle East, and supplied to local supermarkets. The company can engage in all kinds of processing, OEM processing, and other businesses.

Feel free to contact us via email: info@kolysen.com

Copyright © 2025 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist