When cutting a brown paper bag need to pay attention to what issues?

by:Kolysen

2020-08-01

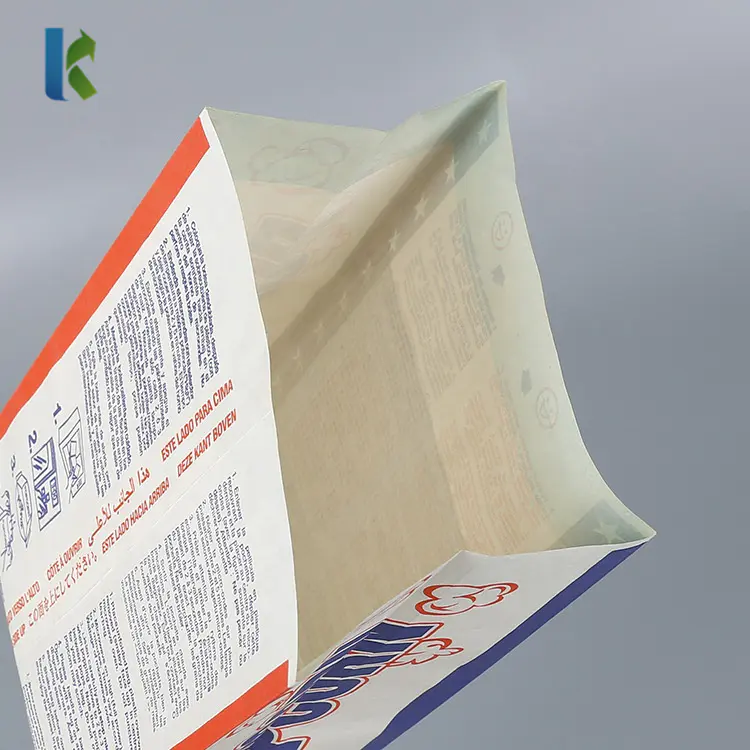

We know that at kraft paper bagpackaging, and before you used in the product packaging according to the different USES often after printing process.

Unlike other kraft paper, printed with a brown paper bag appear easily problem when cutting.

1.

Flat is the most common way of printing paper, offset printing, so as much as possible to prevent dust and other particles with paper into the printer, when cutting according to the cutting of paper to select the most suitable paper cutting knife material and Angle.

2.

Kraft paper, the closer the roll core part, the greater the degree of bending.

For close to good close to the core of the paper, cannot use jump out.

Volume in Gao Kechong kraft paper, cardboard core part of the paper can't use, at the same time, the thicker the cardboard or roll core diameter is smaller, the more volume abandoned boards.

12 inches in diameter (

306mm)

The volume of core can maximize the lower surface rupture and related problems.

3.

To prevent creasing cutting and kraft paper, indentation is mainly due to the conveyor belt, Lu, do not match the speed belt, straightening machine, etc.

aluminum foil paper manufacturers 123 is generally used to aluminum foil paper manufacturers.

All you women out there looking for amazing to dazzle the world try Kolysen Packaging Integration Co.,LTD. latest collections at Kolysen Packaging . Try it!

Kolysen Packaging Integration Co.,LTD. can reassign work or shuffle around assigned tasks if one team member is overwhelmed while others are not, more effectively managing resources on the fly. With detailed overviews and reports, manufacturers also can more easily stay abreast of new developments.

aluminum foil paper manufacturers 123 is generally used to aluminum foil paper manufacturers.

All you women out there looking for amazing to dazzle the world try Kolysen Packaging Integration Co.,LTD. latest collections at Kolysen Packaging . Try it!

Kolysen Packaging Integration Co.,LTD. can reassign work or shuffle around assigned tasks if one team member is overwhelmed while others are not, more effectively managing resources on the fly. With detailed overviews and reports, manufacturers also can more easily stay abreast of new developments.

Custom message