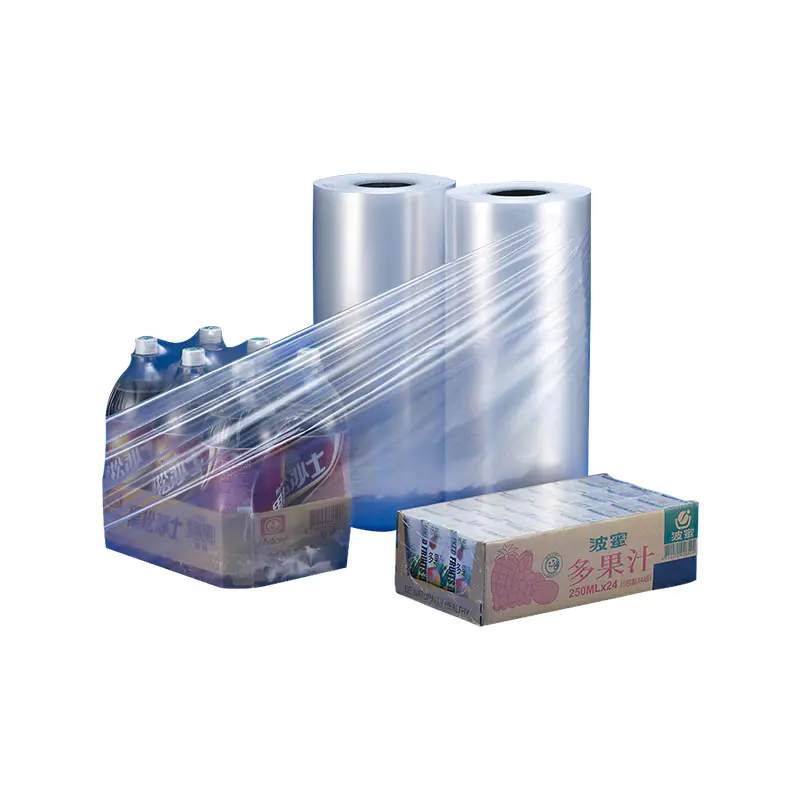

Water heat shrinkable film manufacturing method

by:Kolysen

2020-12-19

The cartoon fold the water bag use heat shrinkable film production process: first made thicker billet membrane, and then heated to proper temperature stretch processing, namely according to difference of billet membrane, can use plain film stretching (

The method of slices)

Blew up, also can use a so-called secondary stretching (

The double bubble stretching)

Methods for the production.

Plain radiographs of the portable water bag stretching is BOPP, BOPET stretch film, such as common production methods, use it to produce all kinds of packing heat shrinkable film, from the control in terms of thermal shrinkage performance of the film, is ideal, the equipment investment is larger, but high output, thus the cost of the product rather low, at the same time the thickness of the product uniformity good, high mechanical strength, can be applied to thickness of thin film, so as to reduce the cost of unit area of the membrane, the highest market competitiveness, thus has developed rapidly in recent years.

Water bag of double bubble stretching method compared with plain film stretching method, large energy consumption, production is low, so the production cost is higher, and thickness uniformity of poor, its main advantage is less equipment investment, at present is mainly used for PVC shrink film, a total of extrusion polyolefin heat shrinkable film production.

For PE heat shrinkable film also can use ordinary blown film equipment, the equipment (

Mainly mouth mould)

Necessary after the improvement, selection of a particular brand of resin and the specific process parameters, application method similar to the ordinary blown film directly manufacturing heat shrinkable film.

Custom message