| Material | Heat Seal Lacquer/Aluminum Foil/NC Primer, details as your request |

| Thickness | 12 micron, customizable |

| Process | One side : NC primer coating. Or printed gold,red,blue etc color. Middle : Aluminum foil Another side : Heat seal lacquer with low melting point 70 degree. |

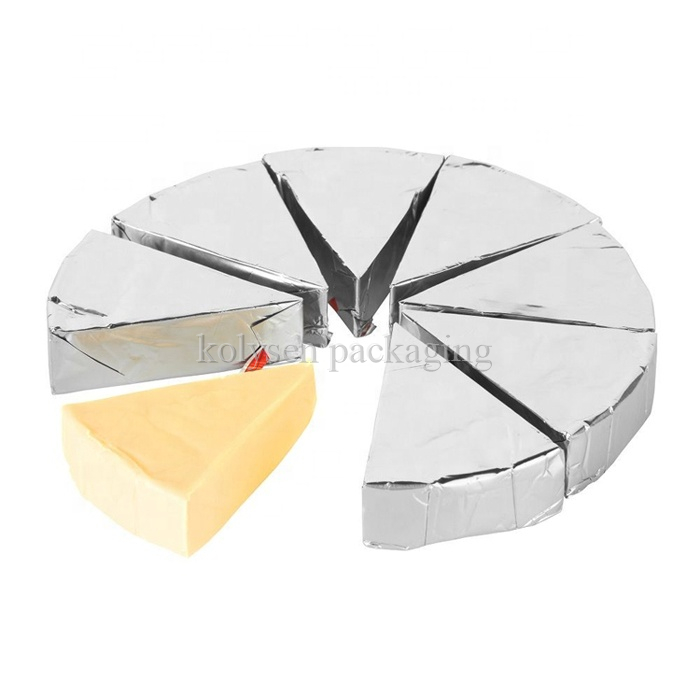

| Application | For wrapping triangle or square cheese. |

| Machinability | The products are packaged automatically with heat sealing conditions of 65-150℃, 0.3Mpa and 0.8-1s. |

| Application | For wrapping chocolate, butter, cheese, candy etc |

The foils for processed cheese are made with an FDA approved heatsealable lacquer especially designed to be compatible with modern packaging equipment. These foils can be used for individually packed portions or for large cheese circles. Whether used with the two foil process (shell and lid) or the single sheet process, the foils can provide a hermetic seal for a long shelf life. This foil is available in silver, gold and a wide variety of colors and shades. The foils can also be gravure printed with one to eight colors.

APPLICATION:

●Used for pack processal cheese, surface in contact with cheese directly. Shell & lid foil, together to achieve triangle & square packaging.

FEATURES:

●High corrosion resistance

●Low temperature sealing

●Excellent barrier against light, vapor and oxygen

●Flexible on the thickness, width and printing design

●Vertically integrated production process

●Multilayer lacquering process

●Excellent, machinability and sealability

●Certified for direct contact with molten cheese

●Recyclable

Copyright © 2025 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist