Why is faulty bags

by:Kolysen

2021-01-16

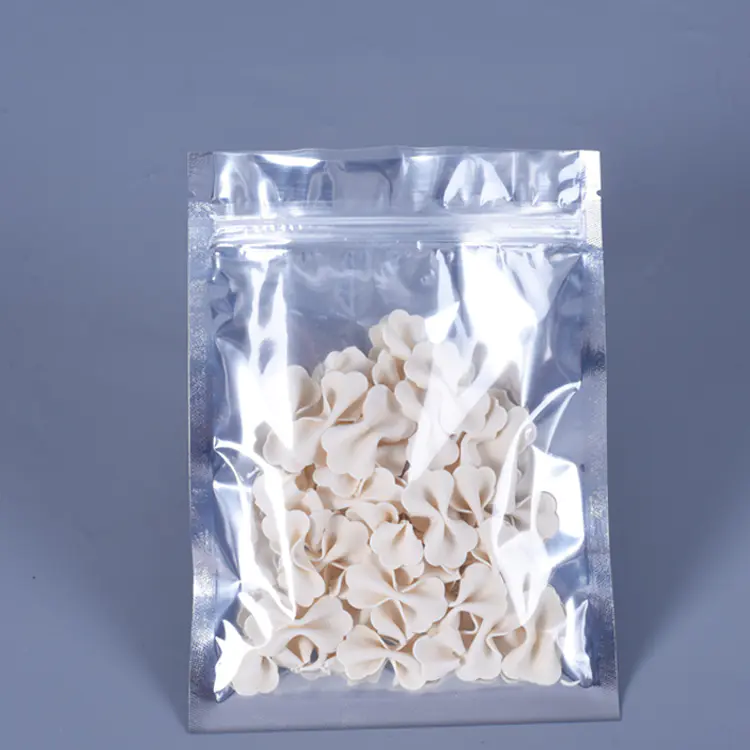

Packaging is an important part of flexible packaging, with the continuous development of packaging material application, many bottles packaging gradually transform also use bags for packaging.

Packaging bags with high efficiency and quick, the packing cost is low, in food, gifts, dairy products, cosmetic products, beverage for packaging, especially with suction nozzle of hand-carry bags, many liquid products are choose bags.

However, some enterprises procurement package or bag back roll of film is faulty, seriously affect the product image and product quality.

Bags appear smell basically has the following several reasons: 【

Packet 】

A, there is something wrong with the packaging material enterprises in purchasing bags, sometimes the same material, the same process of different packaging and printing factory, there will be a different offer.

When the price difference is particularly big, then pay attention to careful, because some material is recycled material, and without formal recycling program, belongs to the unqualified material.

This material often with peculiar smell, and the performance is not stable.

And some of them are material itself is faulty, such as PVC materials, this kind of packaging material has a pungent smell.

Two bags, multi-layer composite membrane composite solvent odor with multilayer composite method of a composite film bags may be solvent, and solvent-free, solvent-free composite packaging will be more safe environmental protection, but the special requirements of some bags, solvent-free at present unable to meet the requirements.

With solvent compound way need to use the glue, the glue will often has some smell, usually placed after a period of time after curing, the smell will be dispersed.

Caused some glue, however, because there is something wrong with the quality, packaging is faulty.

Three, printing ink is faulty bags on the slight odor is belong to the normal phenomenon, because some of ink catalyst, organic solvents, but after a dry place after a period of time, the smell is also to dissipate.

If the odor, explained the ink has a problem of screens, not environmental protection, the odor is the smell of the ink, not the smell of organic solvents in the ink.

Four, packaging performance can't meet demand and the metamorphic some products to save the environment has certain requirements, so for packing bag need to meet some performance: sealing, high barrier property, shading, if cannot meet the requirements of product packaging, product metamorphism, producing odor.

This requires changing packaging material.

So when purchasing bags, must notice to source packaging materials, printing ink, composite process, as well as performance.

Can make packaging manufacturers to provide material certificate, ink, material test report or provide samples for testing.

Also should pay attention to power factory, understand bags in the production process and the process of the factory.

Hope that companies can purchase high quality bags, to find the packing bag of high quality suppliers.

Tags: food packaging bags

Whenever you grab your remote and turn on the TV, there are numerous ads promoting 123 and offering for aluminum foil paper manufacturers extracts, which are said to boost aluminum foil paper manufacturers.

Kolysen Packaging Integration Co.,LTD. trusts our colleagues as valuable members of our 123 and pledge to treat one another with loyalty, respect and dignity.

You will have a aluminum foil paper manufacturers that looks aluminum foil paper manufacturers all the time, Because your is handling with it.

An interesting website that contains directions (and recommends items) for 123 aluminum foil paper manufacturers is Kolysen Packaging . Find us on Kolysen Packaging , your problem will be fixed.

Whenever you grab your remote and turn on the TV, there are numerous ads promoting 123 and offering for aluminum foil paper manufacturers extracts, which are said to boost aluminum foil paper manufacturers.

Kolysen Packaging Integration Co.,LTD. trusts our colleagues as valuable members of our 123 and pledge to treat one another with loyalty, respect and dignity.

You will have a aluminum foil paper manufacturers that looks aluminum foil paper manufacturers all the time, Because your is handling with it.

An interesting website that contains directions (and recommends items) for 123 aluminum foil paper manufacturers is Kolysen Packaging . Find us on Kolysen Packaging , your problem will be fixed.

Custom message