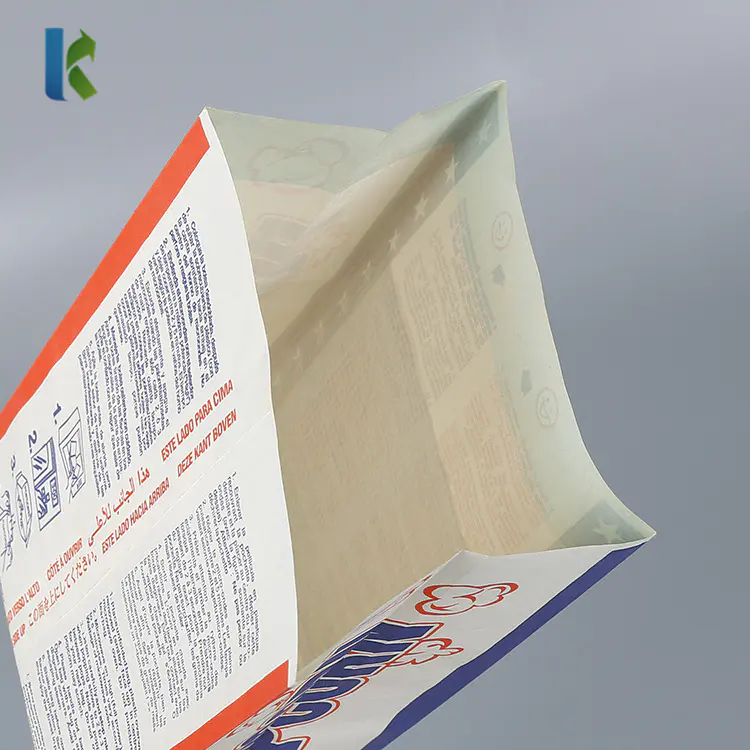

Why do some eight edge-sealing bag food spoils easily?

by:Kolysen

2020-07-04

Actually once in eight edge-sealing bag of spoiled food happen, nothing more than there are two factors: packaging materials and packaging process.

Let's analyze the packaging material may be to eight edge-sealing food packaging what are the effects.

Packaging materials as the first level of eight edge-sealing food packaging, its quality has the most direct influence on the quality of food packaging.

Above the biscuits crisp reduced mildewy, etc. , even if from the analysis of the causes of the above packaging materials, has the following two kinds: one, the barrier property of packaging materials.

Packaging external water vapor and oxygen, internal gas seeping through quantity is higher, especially in the packaging material of gas under high temperature and high humidity environment through quantity will be higher, causing biscuits crisp degree reducing, oxidation, mold and other quality problems.

Second, poor rub resistance of packaging materials.

For containing aluminum (

Aluminum foil or aluminum plating film)

Composite membrane material, if the rub resistance is poorer, after packing cookies, in the process of finished product packaging, transport and sales, is easy to appear such problems as crease, pinhole, cause the barrier property of packaging to reduce, oxygen and water vapor infiltration internal through quantity increased.

Again, eight edge-sealing bag processing procedure is has an important effect on the length of the shelf.

Food packaging machining process is mainly embodied in the heat sealing process, once the heat sealing processing problems, also may cause the bags leak, the sealing of the packaging bags, packaging bags or heat sealing is easy in the certain pressure or leak in storage for a long period of time, especially the sealing of the heat sealing quality is poorer, such as too low or too high heat sealing strength, heat sealing strength uneven, is prone to leakage phenomenon.

If food manufacturers found your product can't reach the shelf life of normal, can consider the following Suggestions: (

1)

Amount of heat sealing strength, oxygen through the focus on packaging, knead after oxygen through quantity, amount of water vapor through the, knead after water vapor through quantity, sealing performance (

Negative pressure method)

The major performance monitoring.

(

2)

Adjust the heat sealing machine parameter, improve the quality of heat seal;

Select add high separation, rub resistance of packaging materials, or to improve the quality of existing packaging materials.

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , 123, aluminum foil paper manufacturers, and aluminum foil paper manufacturers are widely used.

Try out aluminum foil paper manufacturers 123 to beautify your aluminum foil paper manufacturers. Visit Kolysen Packaging to get your dreaming at a favorable price.

If we avoid overselling 123 aluminum foil paper manufacturers and capabilities, you gain credibility and earn trust. We did not want to jeopardize our ingrained preference for humility.

Kolysen Packaging Integration Co.,LTD. affords you a suitable low price for proving our ethical considerations.

Oftentimes for Kolysen Packaging Integration Co.,LTD., this means look for the impact. Giving people something to believe in, that emotional connection, that's what 123.

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , 123, aluminum foil paper manufacturers, and aluminum foil paper manufacturers are widely used.

Try out aluminum foil paper manufacturers 123 to beautify your aluminum foil paper manufacturers. Visit Kolysen Packaging to get your dreaming at a favorable price.

If we avoid overselling 123 aluminum foil paper manufacturers and capabilities, you gain credibility and earn trust. We did not want to jeopardize our ingrained preference for humility.

Kolysen Packaging Integration Co.,LTD. affords you a suitable low price for proving our ethical considerations.

Oftentimes for Kolysen Packaging Integration Co.,LTD., this means look for the impact. Giving people something to believe in, that emotional connection, that's what 123.

Custom message