What is the PE film?

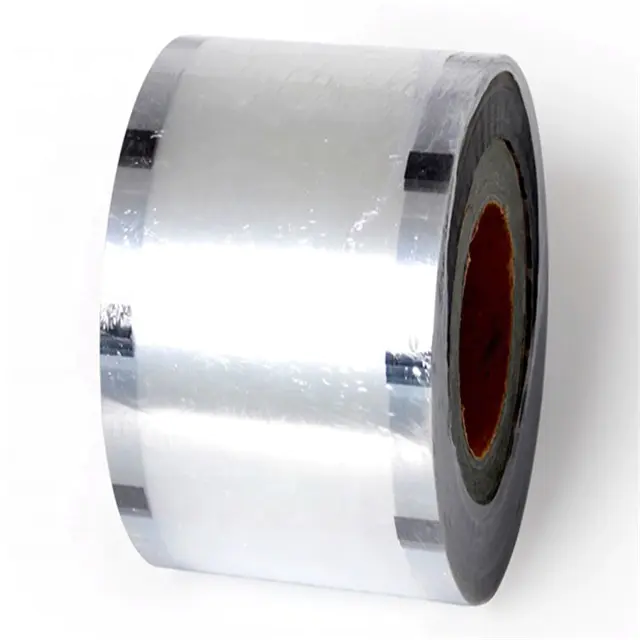

contact soft package industry will not be on PE film stranger. PE, PE for short, this kind of material is mainly used in food packaging, such as the daily life of fruits, vegetables, packaging film, or purchase back of semi-finished products in the supermarket are packed in the material.

PE film can be divided into LDPE, ILDPE, HDPE, and crosslinked polyethylene ( CLPE) Such as the performance of different products, involved in processing way is different, can be divided into blow molding and stretch film.

low density polyethylene ( LDPE)

the density is about 0. About 92 g/cm squared. The transparency of LDPE film with good heat sealing, can waterproof, moistureproof, low tensile strength, tensile elongation, easy to wrinkle, 0. 3 mm below the film, the appropriate tension control is small, and the tension is constant everywhere, especially when heated more deformation, tinted difficult problem. So dry, thin film surface temperature not too high.

according to PE membrane film forming process is different, can be divided into the blown film ( IPE) , stretch film, CPE) , low foaming film to wait for a few kinds. Among them, the IPE film tensile strength and open sex is better than CPE film, using positive printing way, can make food bag, garment bag, etc. ; CPE film thickness, the surface gloss, transparency and heat sealing is better than IPE film, positive and negative can be printed, but the production costs are relatively high, and CPE film is mainly used as the lining of the compound bag and cosmetic, pickles and cakes packaging; Low foaming decorative film good, quality of a material is solid, not easy to draw texturing, using positive printing, generally used as a New Year pictures, trademarks and hand carry bag, etc.

medium density polyethylene ( MDPE)

the density of MDPE film about 0. 93-0. 94 g/cm squared, performance between LDPE film and HDPE film.

high density polyethylene ( HDPE)

density at zero. 94 - 0. Between the 965 g/cm squared. HDPE film heat resistance and mechanical strength is better than LDPE film, tensile elongation is small, thin film thickness is in commonly 0. More than 3 m, but the transparency is poor. Using positive printing, mainly used as vest bags, garbage bags and liner bags, etc.

crosslinked polyethylene ( CLPE)

because of CLPE than other polyethylene products have higher heat resistance, tensile strength, thermal shrinkage and barrier property and its USES in further expansion, is mostly used as heat shrinkable packaging film.

in general, with higher density, mechanical properties and the blocking performance will improve accordingly, heat resistant, was born. The same density polyethylene, because of the different film forming process, also have different properties between them. This is because salivate method can rapidly cooling, low crystallinity, high transparency, turbidity is small, but the molecular arrangement more hasten is no rules, so the barrier property is small, the transmittance is bigger, low elongation, tear resistance is poor.

It has become necessary for Kolysen Packaging Integration Co.,LTD. to continually cultivate, develop and update their skills to work successfully alongside high-tech.

More about the most suitable , visit Kolysen Packaging to get your offer!

Kolysen Packaging Integration Co.,LTD. needs to ensure we're resolving customer issues as quickly as possible. By doing so, it leads to positive customer experiences and brand loyalty.

We began investing in our workforce and negotiated deals with major suppliers and providers to lower the cost of equipment so the technicians could enhance the competitiveness of 123 right away.

123 provider at Kolysen Packaging offers a wide variety of in many options. quality is absolutely ensured if you choose us. welcome to visit our factory.