Milk powder in small packaging bags | powder | milk powder bags custom - Food packaging manufacturer

by:Kolysen

2020-12-08

In recent years, as people's living standard is increasing day by day and the world famous food company to enter the Chinese market, China's dairy industry presents the vigorous momentum of development, which have high quality, high nutrition powder consumption is growing.

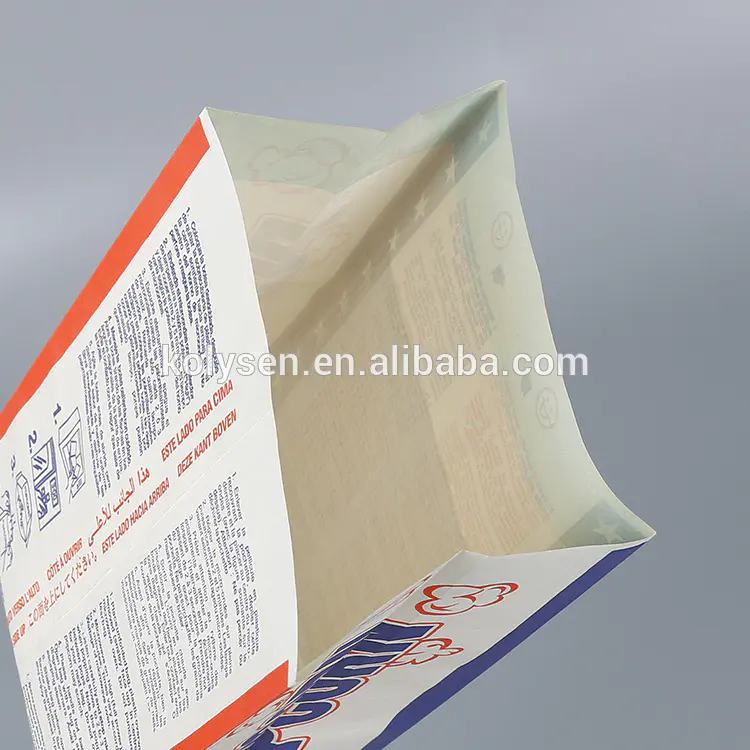

At present, the milk powder packaging that sells on the market are mainly metal cans and milk powder bags in two forms.

Metal cans sealing good, long shelf life, but its production and transport costs are high, so, only several large well-known dairy enterprise application forms of this kind of packing on the part of the product.

The same quality cans of milk powder, the market prices are generally more expensive than bags of milk powder by more than 30%.

Corresponding to this, the dry type composite powder with an alternative tin trend bags have higher and higher market share gradually.

Among them, including the structure of the aluminum foil milk powder packaging cost is higher, but the shelf life is long, generally can be up to a year and a half to two years.

Aluminum plating structure of milk powder packaging costs are relatively low, but life is short, usually no more than a year and a half.

For the BOPP structure, because of the heat resistant properties of BOPP material itself is bad, generally used is not suitable for automatic packaging machines, mainly used to make bag, manually packaging.

When milk powder need long distance transport or storage and transportation in the process of packaging material easy to squeeze the rub, if choose this kind of packing, with aluminum foil is critical to the performance of the composite materials, commonly used milk powder packaging composite material design is PET/AL/CPP, PET/AL/PA/CPP, PET/NY/AL/NY/CPP, etc.

For packaging materials manufacturers, they all know that milk powder bags mainly improving design, provide more convenient;

Improve the structure of the composite materials to meet the more stringent requirements.

The future development trend is multilayer composite gas impermeability of plastics, functional, and with the development of biodegradable plastic is more quickly.

Strip packing, that is, independent packaging, we are not unfamiliar, in condiments, solid beverage, and other products, widely used in always with its easy to carry and clean characteristics was welcomed by the consumers.

Infant formula to strip packaging, compared with the large packaging, light easy to carry, won't cause burden for parents with young children travel;

Its sealing is stronger, when using, need not measuring cup weighing, one at a time, there is no many times the risk of pollution.

Strip packing's advantage is obvious, but for milk powder production enterprises, to enable the strip milk powder bags, also is not achieved overnight.

First of all, the increased cost of packaging, this is the most enterprise has strip packing obstacle;

Second, the high-speed strip packing makes the existing single large packaging production line speed of pressure;

Finally, production date, batch number, shelf life etc. The information in the packaging must be identified on the strip packing to ensure good quality for the separate packing of monitoring and tracing.

Overall, strip packaging infant formula will to its security, convenience, change the infant formula industry, lead the new fashion of the milk powder industry.

Custom message