Medicinal composite membrane structure and the common quality problems

by:Kolysen

2020-12-04

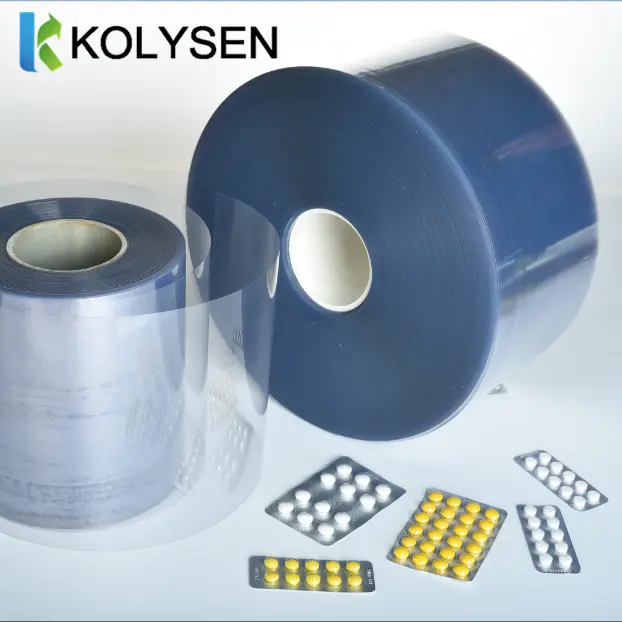

Medicinal composite membrane, as the name implies, for all kinds of plastic, paper, metal of composite membrane by adhesives, thickness is less than 250 um.

Ordinary common medicinal composite membrane structure for PET/PE, PET/PA/PE, PET/AL/PE, PET/VMPET/PE, VMPET/CPP, PT/AL/PE, PAPER/AL/PE, good drugs commonly used in stability.

Resistant to cooking the common structure of PET/AL/CPP composite film, durable thorn common composite membrane structure of PET/PA/AL/PE, often used for high temperature steaming and vacuum packaging products.

Special blocking function is a common structure for PET - composite membrane

Si/PE, PVA/PE, or more PET/AL/PE composite membrane, used to cut off water, cut off oxygen, avoid light, or cut off oxygen, water, and at the same time avoid light products, generally in view of the contents of sensitive products.

Common quality problems of medicinal composite membrane 1 solvent residual solvent residue is the most common composite film quality issue, solvent residue migrated to a drug, can be directly affect drug safety.

Suggest pharmaceutical factory incoming testing each batch inspection, may also choose the production of solvent-free composite products.

2 peel strength peel strength is unqualified, is complex in the process of packaging material in the production process and curing process caused by unstable, on behalf of the packaging materials factory production technology experience and level of key indicators, is a drug company incoming inspection and supplier quality audit need to focus on the problem.

3 compatibility problem of composite membrane transfer drugs to transfer is the main source of heat sealing layer of plastic additives, or adhesive composition, or negative glued to the inner layer of ink.

4 barrier performance materials blocking performance including water vapor transmittance and oxygen transmittance is unqualified.

The above indicators are directly affect the protective function of drug, determine the validity of the drug.

Lead to these problems is the main reason of the packaging factory to choose the base material quality is not stable.

Suggestions per batch inspection, and monitor supplier base material varieties, shoulds not be too low compression purchasing cost.

5 above problems mainly comes from the inner base material friction coefficient of friction coefficient, the parameters directly affect the operation of composite membrane in pharmaceutical factory packaging machine smoothly.

Custom message