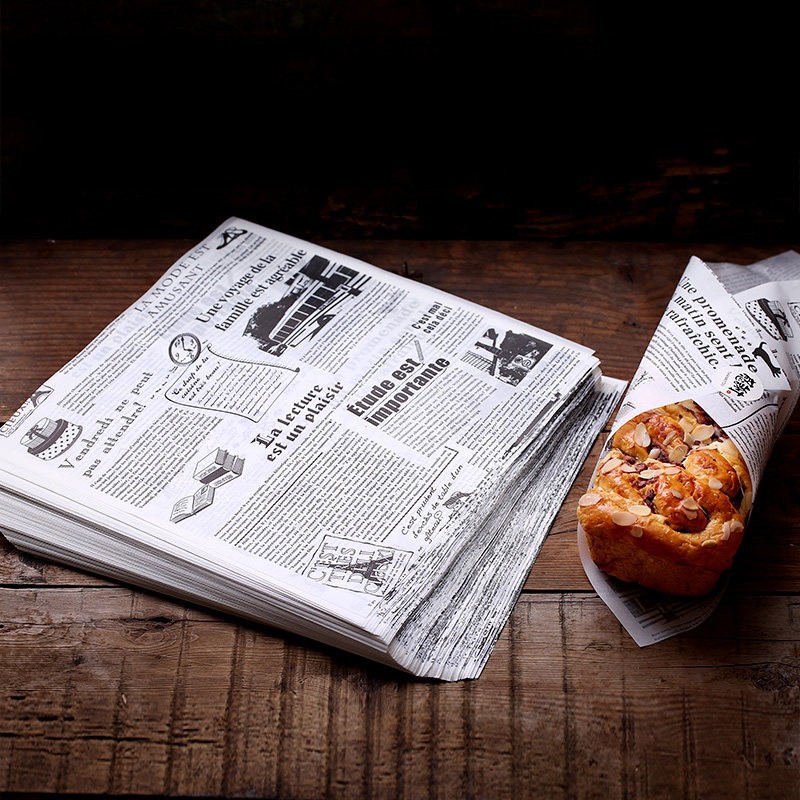

Custom Printed Greaseproof Paper

◪ It's Non-Toxic

◪ Stops oily food applications

◪ Top quality high wet strength

◪ Designed for both hot and cold foods

◪ Made naturally without any coatings

◪ Vegetable based inks used for printing

Greaseproof paper is the perfect solution for fried foods, greasy foods, hot & cold foods, oils & sauces, heavy dishes, basket liners, tray liners, food wraps and so much more! This is the most versatile sheet on the market today! Greaseproof paper can be custom printed with your logo and delivered to your door in just 1-2 weeks.

Copyright © 2026 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist