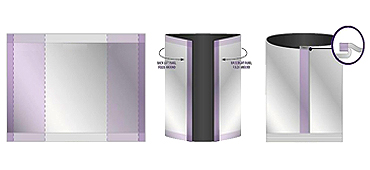

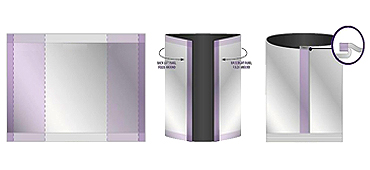

Center Sealed

Center sealed pouches are a prevalent and low-cost, flexible packaging method. It can be made from multiple types of packaging films, where the packaging is a center seal at the back where two ends of the packaging film meet. It is a low cost, water and tamper-resistant packaging that is used across multiple industries. It can bear up to 10 kilograms of weight and it commonly used for packaging whole grains, ready to eat food products, snacks, chips, biscuits, pharmaceuticals, electrical appliances and more.

Custom Service:

The bag size, material structure, thickness and printing as well as bag shape can be totally customized as per customers' requirements.

| Item | Printed Pouches With Centre Seal |

|---|---|

| Materials | Mono or multi-layer laminates using materials such as OPP / CPP / PET / PE / PP / NY / ALU / MetPET |

| Finish | Available in a matt, gloss, kraft, tactile, paper feel, de-metalized, unprinted and registered matt finish |

| Feature | Environmental protective, excellent barrier property, eye-catching printing, safety food grade |

| Use | Snacks, nuts, dried food, dried fruit, seeds, coffee, sugar, spice, bread, tea, herbal, wheat,cereals, tobacco, washing powder, salt, flours, pet food, candy, rice,confectionaries |

| MOQ | Stock bag: MOQ 1 Piece Custom bag: MOQ 20000 Piece per size or per printing We accpet small order if our current products is ok for you. Just contact us. |

| Payment | 40% deposites by TT upfront, 60%balance before shipping |

| Lead time | About 15 working days after receiving formal order and deposites |

| Trade terms | FOB Xiamen,CIF,CFR,EXW etc. can be negotiable |

| Shipping way | By sea, by air, by courier(DHL,FEDEX, TNT,UPS etc), as your require |

Copyright © 2026 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist