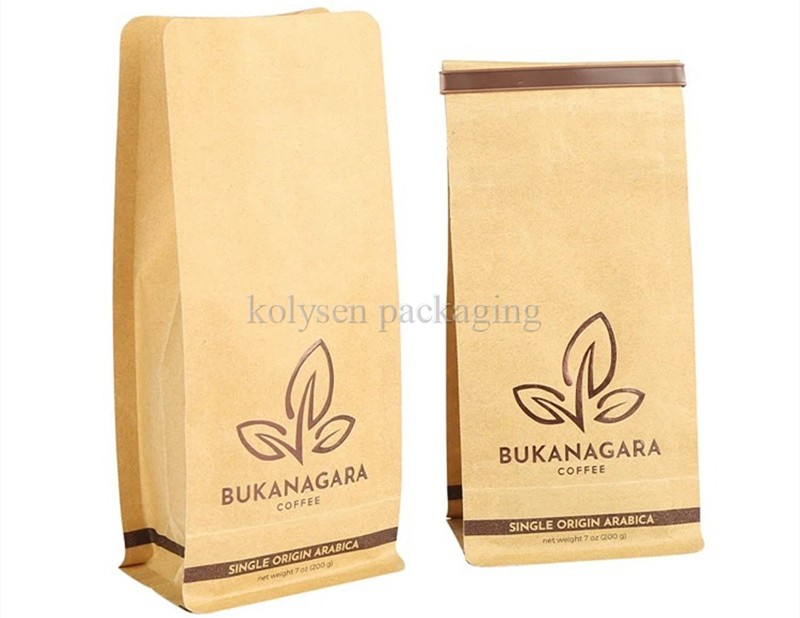

Flat Bottom bag also called “3D pouch” or “box Pouch”; the bag provides a good function of standing as like as a box; so the bag style can make a good design & more high class display on the shelf. The bag has an excellent printing area of 4 panels, the front & back, 2 side gussets can be printing customized designs and logos.

The bag can be made of different materials require for different products, like pet food, confectionery & snacks, beverages, coffee, dry food & premium products. As difference requirements, it can add many optional functions: like reclosure zipper, euro hole punch, handle, degassing valve, laser score for easy tear; that provided a perfect solution & multiple values in the same bag.

The quad seal bag was an innovative packaging which developed in the market, it brings the product developed more excellent design & multiple selections from traditional packaging bag; all the products will earn high value and best advertisement depend on an excellent packaging.

| Materials | Mono or multi-layer laminates using materials such as OPP / CPP / PET / PE / PP / NY / ALU / MetPET |

| Size & Thickness | Customizable, as per your requirements |

| Printing Method | Per requirement, gravure, digital, spout UV, hot stamping, stickers |

| Style Options | Flat Bottom, Stand Up, Side Gusset, Quad Seal, Middle Seal,Flat Pouch, etc |

| Option Available | Rounded Corners, Tear Notch, Hole Punches, Zipper, Window, Hang Hole, Valve, Tin Tie, etc. |

| Standard Finishing | Available in a matt, gloss, kraft, tactile, paper feel, de-metalized, unprinted and registered matt finish |

1. Provide us with detailed information about the pouch you need, like application, size, artwork, structure, and thickness, etc.

2. We will quote accordingly after we get all the details about the pouch.

3. Once the price is confirmed by both parties, we will start the processing of the artwork.

4. Setting up the color standard.

5. Confirm drawings and sign contracts.

6. The buyer needs to prepay the cylinder (printing cost) and a 30% advance payment on the order.

7. We will start producing quality products for you after then.

There are different types of flat bags for you to choose from.

Flat bottom bags have different material ingredients, allowing you to choose the perfect choice for your products.

Aluminum Flat Bag: This bag is a combination of metalized film and tin foil. Tinfoil bags are highly durable and insulated.

Kraft Flat Pouch: This is a type of coffee made from cardboard that is popular for its lightness and user-friendliness.

Plastic Flat Bags: Plastic coffee bags are polymer bags that are perfect for storing products.

Clear Flat Bag: This is a type of bag where the contents of the bag can be seen.

All types of flat bags are dynamic and flexible.

You can use them in the packaging of various products and they are a suitable substitute for folding and corrugated cartons.

Copyright © 2025 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist