Compound bag making process

by:Kolysen

2021-01-04

Compound bag bag making process of compound bag production process: 1.

Customer document confirmation: provide their own design source document or pictures, samples, and we communicate, after we provided quotation after the customer agrees to the two sides signed the contract, we arrange the production after deposit payment.

2.

Customer required material bag confirmed: communicate with customer for material, confirm the bag material structure (

Such as tea bag material: opp after aluminum foil after PE, pet after aluminum foil after PE composite bags, food bags)

According to customer needs or Suggestions are given by us.

Customer confirmed to arrange the next step.

3.

Copper factory manufacture of copper: to provide the source document do printing copper to copper plant layouts, communicate with the customer to confirm the printing colors, how many COINS.

After the customer sign the copper factory do version.

Copper price is according to the regulations of the copper plate factory general 300 - each color

600 yuan, a color needs a coin.

Copper plate can be used repeatedly, generally better copper factory production of copper color is better.

(

Need to play version of the client to arrange the version fee, play and do the production process, can produce operating expenses, general play is the proofing charge standard: 1500 + copper cost, make the version is not return)

, so in order to save money, we generally do not recommend client version.

Food is 20 years of compound bag production factory, for the production of compound bag has plenty of experience, so we usually give customers we produce bag customer reference.

4.

Fixed materials: inform raw materials suppliers, according to the customer needed the material order 5.

Composite: the material back to arrange for the first time to use the computer.

Compound bag usually consists of two layers or three layers, four layers of plastic film materials, base material, or compound and into, such as kraft paper, and the production of compound bag is not a simple, need workers carefully every step of the operation.

6.

Printing: composite good arrangement after printing.

Color printing to customer in advance to the factory confirmed that the printing master toning introduced. a preliminary printing, customers ready to see the color confirmation signed by, and then to print.

(

Distant customers we will arrange to send the color draft, or shooting scene to the customer for confirmation.

)

7.

Composite: after the completion of the printing for the second compound, the printing surface composite layer or two layer, three layer material.

This compound is completed.

8.

Drying: composite material,

Called composite membrane)

To cure, also is dry.

24 - materials required at this time

48 hours or longer time, let the glue dry, printing color stereotypes can step after bag bag out of the dryer.

9.

Cutting: the first good composite membrane were cut, cut into small bags.

10.

Bag: cutting good bag bag making machine, after debugging bag making master technology made according to customer required bag shape.

11.

Cut the bag: bag bag or cut die cutting.

Such a bag is completed.

Now take pictures to the customer.

12.

Product checking: complete bag for product inspection, the staff will check carefully the bag printing, set, and so on, through the quality rear can notify the packaging boxes.

13.

Storage: packing good bag into the factory inventory, waiting for the customer inspection.

14.

Customer pick up the goods: the customer pick up the goods before the inspection, in line with expectations after scoring the last payment, we arrange delivery.

According to the customer request to arrange the logistics or delivery.

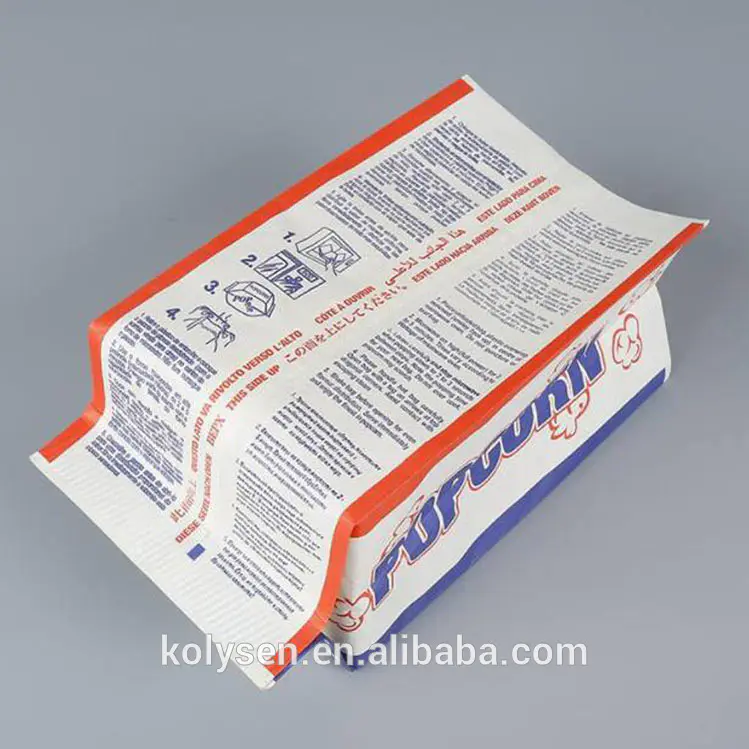

Welcome to inquire order composite bag, food bag, tea bag, face film bag, packaging film, etc.

We have all kinds of bag samples for customer reference.

Food packaging has been committed to the production and development of lu: su composite bag, can undertake all kinds of complicated pocket.

Welcome field trips.

Custom message