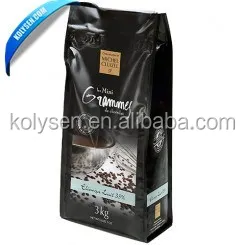

black coffee bags that hold 300-500G with gas valve and printed on the package

1. material: PET/PE, PET/AL/PE

2. with one-way Goglio degassing valves

3.outstanding barrier properties

4. appealing surface

Coffee Bean Packaging Bag

(Multi layer laminated, with one-way degassing valves, bright printing, outstanding barrier properties, high performance lamination, appealing surface, oil/gas/water proof)

Zipper / Hang hole / Laser score / Tear notch / Valve / Spout / Demetalized window / Wicket

1) Material: Laminated material/ multilayer PA/PE, OPP/PE, PET/PE, OPP/CPP, PA/CPP, PET/PA/CPP, PET/VMPET/PE, PET/VMPET/CPP, PET/AL/PE, PET/AL/CPP or according to your request

2) Grade: Food grade, Meet FDA/ EU/ ISO standards

3) Size: Customized

4) Printing: State of the art 10 color graphic packaging printing

5) Design: Side Gusset, Quad Sealed, with valve/zipper/tin tie

6) Free sample: Various types from our current stock

7) Features:

*High quality food packaging printing for film on the reel and pre made bag applications.

*Wide range of film substrates for food packaging applications in both single web and laminated form.

*Surface and reverse printing to exacting standards.

*Quick set up press for specialized short run work.

*Food Packaging design and origination service available.

1What types of bags?

Answer:Bottom-gusseted bag, with or without zipper 3sides sealed bag, with or without punch hole center-seal bag, with or without tear nick stand-up pouch with or without zip Quad-sealed bag, with or without air valve and so on.

2,What is laminated material?

Answer:A material which is composed of multiple layers of different material which are joined together to form a single sheet. The component layer are bonded suing adhesives. The objective of combining different material together is to create a new material with a combination of properties not available from any single material.

3,What is “metallised” film?

Answer:Metallised film is a plastic which has a thin coat of metal applied to it. Generally aluminum is used. The most common way of producing metallised film is known as vacuum metallisation.

Metallised is achieved by heating aluminum wire until it literally evaporates and coats the plastic film. Plastic films commonly used are OPP,CPP and PET.

The aluminum-coated film has shiny decorative surface effect. Additionally metallised film has added barrier properties and in a laminate structure can enhance both gas and moisture protection. Metallised film is often seen in applications such snack pouches coffee packs and candy wrappers.

4,PET or OPP printed layer?

Answer:

Advantages of PET

-Greater strength resulting in better control for repeat length and slitting size.

-Higher heat resistance (~250°C)making it the preferred choice for fast speed packing machines (OPP can only withstand up to 180°C)

Disadvantages of PET

-Higher cost in comparison to OPP

5,Why is Nylon needed to my bag?

Answer:Though its price is high, Nylon film is good for oxygen barrier and impact strength.Especially when the bag is to be hot-filled through or drop resistant is needed, it is necessary.

CONTACT ME

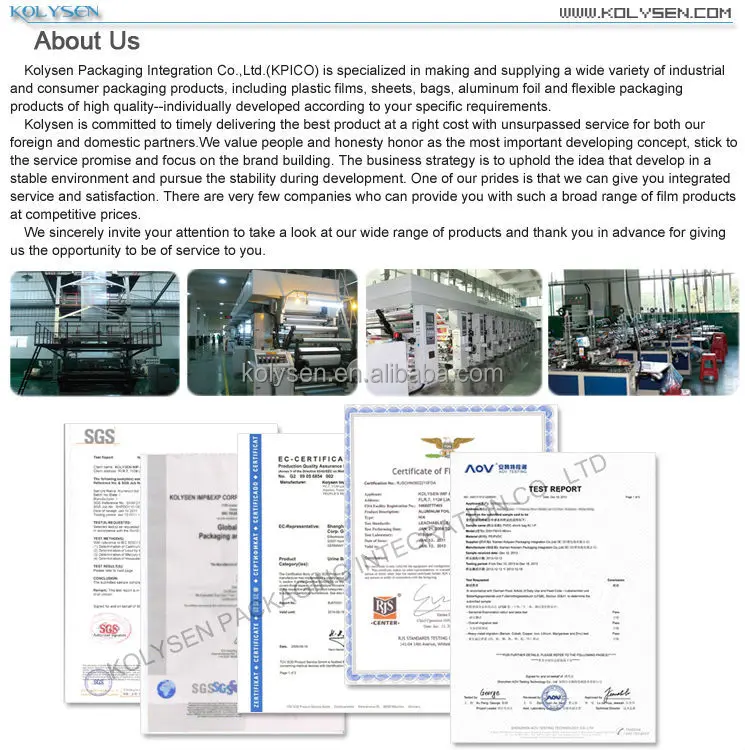

Kolysen Packaging Integration Co., Ltd.

URL: www.kolysen.com

Tel: 0086-592-8333630

Fax: 0086-592-5125630

Cell: 0086-15060827227

Skype:Amanda-Kolysen

email :linda at kolysen.com

Copyright © 2026 Kolysen Packaging Integration Co., Ltd. | All rights reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist