Aluminum foil bag and self-supporting bag - How much do you know that bag?

by:Kolysen

2020-11-18

Self-reliance bags and aluminum foil bags are widely used in the work of packing two kinds of bags, you know, self-reliance bags and bags of concrete application?

Today a professional flexible packaging producers packing just to clarify one by one for you.

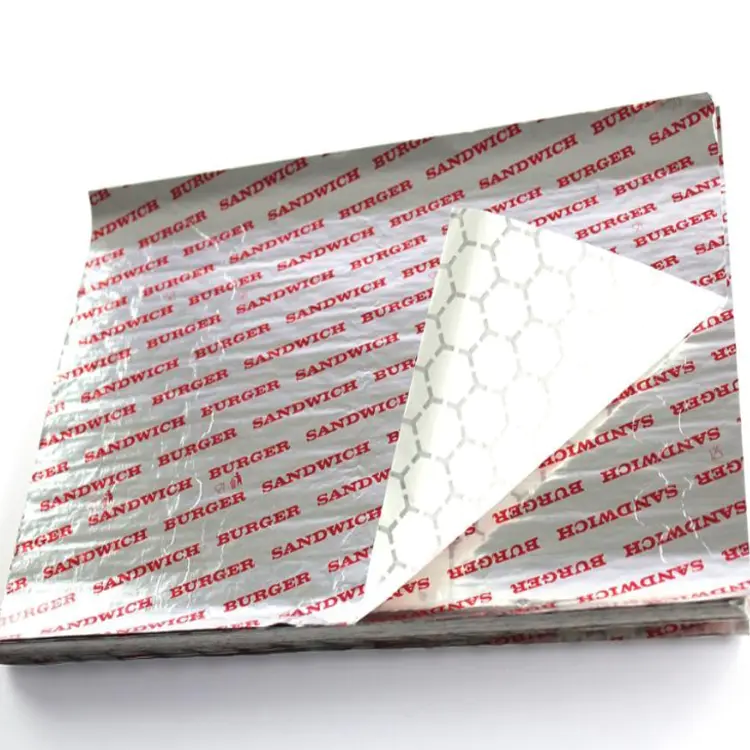

The aluminum foil, aluminum foil bag bag is the darling of the plastic flexible packaging, many products packaging can use aluminum foil bag, so the production of aluminum foil bag what way and needs pay attention to what?

Strip of aluminum foil bag is usually several materials to compound, and then bag making according to customer requirements, in the high temperature cooking foil bags there are generally four or more compound and into a variety of materials, four layers: PET/AL/NY/RCPP, anti-static aluminum foil bag, usually is compounded three or four layers, three layers: PET/AL/PE, four layers: PET/AL/NY/PE, anti-static aluminum foil bag has divided into double anti-static aluminum foil bag and anti-static aluminum foil bag one side!

1, aluminum foil bag materials: PET, aluminum foil, PE film, PET, aluminum foil, CPP film.

2, the characteristics of aluminum foil bag features: resistance to corrosion, smothering, avoid light, high temperature resistant, can be vacuum.

3, spell selection: spell, the more the lower the capital, according to the equipment condition to choose suitable specification, can be a dramatic drop in loss.

4, adhesive selection;

Early pick large viscous force, high solid content, invasive good adhesive.

5, aluminum foil bag making craft glue quantity is approximately 1 white membrane.

5 times.

When printing to full bottom or larger area, amount of glue should be further expanded.

After 13 hours after the first pass of composite curing compound for the second time, product curing 72 hours.

Aluminum foil without flattening roller, surface into the composite roller.

Tension control.

Baking oven, the temperature of the composite roller travel as far as possible.

Second, self-reliance self-reliance bag bag, also called vertical bag, stand bag, the packing bag of mean on that can stand up straight, but rich picture and text printing.

Self-supporting bag is made of a variety of plastic film composite back after bag made of bag making machine, used for packaging clothing apparel, food, medicine, industrial products, daily necessities, etc.

Self-supporting bag is a kind of can stand plastic bags, there are generally two maybe three layers, four layers of material composition such as PET/PE, PET/CPP, OPP/PE, OPP/CPP, PA/PE, PET/AL/PE, OPP/AL/PE, etc. , aluminum foil composite materials (

AL)

Called self-reliance aluminum foil bag, and composite plating aluminium material called self-reliance aluminized bag, based on different terms have different materials.

Self-supporting bag printing and valve bag does not exist significant differences.

The only difference is that, self-supporting bag bottom organ, no matter things can't installed to be able to stand up, and will not be able to valve bag.

Self-supporting bag and packaging bag making machine, production out of the bag type is also different, independent generally called the bottom of the plug on the bottom of the bag, it is because the bottom bags stand to adjust themselves, such as in a combined with bone, and self-reliance valve bag, also called self-supporting zipper bag.

Self-supporting bag because its can be independent to stand up, has a better show shelf is adjustable, many are passionate about this kind of bag type, so the self-supporting bag also is widely used in clothing, food, electronic hardware, daily necessities, medical supplies and other aspects.

Custom message