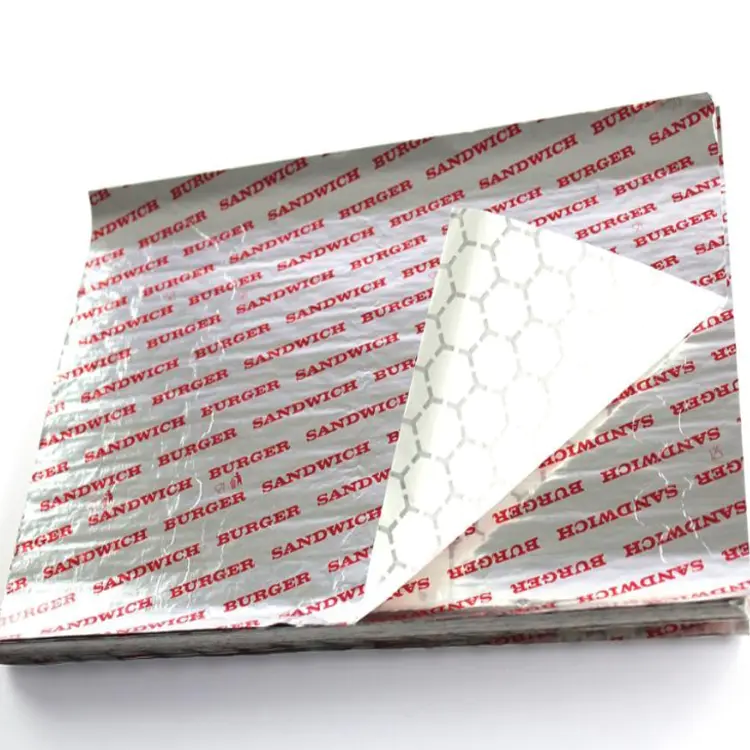

Aluminum bag printing badly aligned and reasons of the poor heat sealing strength, do you understand?

by:Kolysen

2021-01-21

Recently we order of aluminum foil bag is growing, more and more.

With the daily work, summarizes some problems and experiences -

—

Aluminum foil bags badly aligned and poor heat sealing strength.

Everyone knows what reason be?

This small make up to today and you talk about two questions: one, aluminum foil bags badly aligned reason: mainly is the gravure roller diameter deviation;

Because of the plate is not straight, caused by the deformation;

Film open reel tension control over uneven or gravure film thickness is uneven, falbala;

Plate cylinder and seal pressure on both ends of the cylinder pressure is uneven or multi-color overprint do not match the plate between the pressure.

Intaglio printing misregister were the main quality problems, there are a lot of reasons.

Practical experience obtained mainly machinery and equipment reasons, because of mechanical equipment in the long-term survival is running, at ordinary times did not pay attention to maintenance and maintenance, mechanical structure parts wear or obstacle, can cause misregister.

This requires periodic inspection and adjust the equipment.

Second, the aluminum bag heat sealing strength poor (

1)

Aluminum foil bag heat sealing materials different kinds of heat sealing material, the influence of different heat sealing strength;

The same film products of different polymerization methods, different heat sealing strength;

The thickness of the material, uniformity, could also affect the heat sealing strength;

Heat sealing layer of different processing methods, such as blow molding, cast film, etc. , influence the heat sealing strength.

(

2)

The influence of aluminum foil packaging composite film processing technology printing ink temperature resistance is poor or in ink additives not appropriate, under the high temperature of bag making, printing layer falls off, heat sealing strength decreased.

Heat sealing side should be designed without pattern.

In composite process adhesive selection is very important also, binder ratio, viscosity parameters such as the reasonable or not will affect the sealing strength.

(

3)

Bag making process affect the sealing side of cooling after hot sealing is not enough, finalize the design is insufficient, can't eliminate the internal stress, impact strength and appearance, should check in time, strengthen the cooling water circulation system.

Heat sealing, the more the higher the heat sealing strength.

Longitudinal heat sealing number depends on the longitudinal welding knife effective length and the ratio of the bag length;

Lateral heat sealing number by the lateral heat sealing device of combination number combination.

Custom message